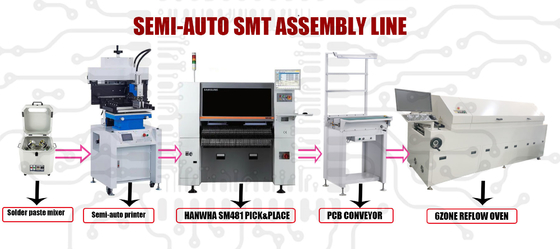

Economy SEMI-AUTO SMT PCB ASSEMBLY PRODUCTION LINE EQUIPMENTS

We provide you both semi auto and full automatic smd assembly machines in China

This semi auto matic line including bellow machines(also can change depends on your requirements)

1,Solder paste mixer

![]()

The semi auto matic smt production line solder paste mixer specification:

| Solder paste mixer operating voltage | PowerSupply:AC220V/110V OPTION |

| Solder paste mixer running speed | Arm RotationSpeed1400RPM revolution: 400RPM speed ratio: 4:1 1400RPM rotation: 350PRM |

| Solder paste mixer working capacity | |

| Container | 500 g / 1000 g (fixture must be replaced) |

| Stir two cans of solder paste at the same time | 500G1000g One/Two container operation. |

| Solder paste mixer mixing time | Workingtimer1—99 minutes digitally adjustable |

| Solder paste mixer operation | Operational light touch button, easy to operate |

| Solder paste mixer fixture function | Holding universal fixture, suitable for all kinds of brand solder paste cans |

| Solder paste mixer running noise | Noise low running noise <35dB |

2,Standard semi auto stencil printer for SMD assembly line

![]()

| Printing area | 300×400mm/500/600/800 OPTION |

| Substrate size | 300×500mm |

| The thickness of the substrate | 0.2-2.2mm |

| Fixed printing position | PCB Outer Or Pin Positioning |

| Bedplate fine-tuning | Front/Back±10mm R/L±10mm |

| Printing precision | ±0.05mm |

| Machine repeatability | ±0.02mm |

| The minimum distance between | 0.35mm |

| The use of air compressor | 4-6Kgf/Cm2 |

| Use the power supply | 220V 50/60Hz 100W |

| Machine size L * W * H | 800×1000×1650mm/ |

| Machine weight | 300Kg |

| interface | English/chinese |

3,SM481 PLUS Hanwha pick and place machine

![]()

SPECIFICATION:

1, 10 mouth single arm design, the maximum speed can reach 40000CPH.

2, the use of flying camera + fixed camera identification, greatly improve the ability of large components mount.

In addition to the ordinary materials within 0402 mount, it has excellent stability in mount BGA, IC, CSP and other large and medium-sized materials.

3, monorail design, optional maximum PCB input size 1500x460 configuration.

![]()

SMT PCB CONVEYOR SPECIFICATION:

![]()

| Model | 500MM | 600MM | 800MM | 1000MM | 1200MM | 1500MM |

| Outline size | 500*670*880 mm | 600*670*880 mm | 800*670*880mm | 1000*670*880mm | 1200*670*880mm | 1500*670*880mm |

| PCB width | 500*50~350 mm/460MM | 600*50~350 mm/460MM | 800*50~350 mm/460MM | 1000*50~350 mm/460MM | 1200*50~350 mm/460MM | 1500*50~350 mm/460MM |

| Transfer speed | 0-12m/Min | |||||

| Conveyor Direcion | LEFT-RIGHGT/RIGHT-LEFT | |||||

| Power supply | AC220V/110V 50/60HZ | |||||

| Main motor Power | 15W | |||||

| Track Fiexed Edge | front fixed(back fixed) | |||||

| Transport Height | 900±20mm | |||||

| Net weight | 41kg | 48.7kg | 48.9kg | 55KG | ||

6ZONE SMT REFLOW OVEN FOR SMD ASSEMBLY LINE:

![]()

| Machine data |

| Model size: L3800×W1000×H1450mm |

| Power supply: 3¢ 380V 100A 50/60HZ |

| Starting power: 0KW normal working power 6.0KW |

| Weight: 700KG |

| Transmission part |

| Stainless steel B-shaped mesh belt + blackened and hardened guide rail |

| Mesh belt width 400MM, guide rail width adjustment range: 50MM—350MM |

| Transmission direction: from left-right or from right-left optional |

| Transmission speed: 0—5M/min frequency conversion speed regulation |

| The height of the mesh belt from the ground: 900MM±0MM |

| Heating characteristics |

| The whole machine is designed for lead-free process |

| Heating zone: up 6 down 6 |

| Cooling area: double-layer constant-flow fan cooling |

| Length of heating zone: 300MM |

| Heating time: normal temperature to set temperature time ≤ 0min |

| Heating sequence: heating from the middle to both sides one by one, saving 1/3 of electricity |

| Temperature control accuracy: ±°C (depending on the height of the furnace) |

| Insulation performance: the temperature of the upper cover does not exceed 45 degrees at a high temperature of 50 degrees |

| Temperature control method: balance chain + analog voltage adjustment |

| The upper and lower temperature zones can be independently operated and controlled |

| heating parts |

| Imported high temperature resistant motor, variable frequency to adjust the wind wheel to transport the wind. |

| Stainless steel nickel heat pipe, with heat sink for even heating |

| The temperature detection time is increased from the original three seconds to 0.1 seconds |

| Efficiently accelerate the air duct to provide sufficient circulating air volume |

| Forced ventilation device to ensure that the flux vapor does not leak |

| Transmission part |

| Digital governor, Taiwan STK motor 1:150 gear box ratio |

| The mesh belt can be adjusted freely |

| Double gear synchronous transmission, stable operation |

| Grease roller filling system, |

| body structure |

| Overall frame welded structure, sturdy and durable |

| Computer spray paint, the surface is smooth and textured |

| The preheating and drying zone is extended in structure, so that the pad oxidation cleaning ability of the equipment and the rosin recovery ability are strengthened. |

| Electric cylinder open/close cover system. |

| Double cover opening control system (gas spring cover opening + cylinder cover opening) |

| There are detachable interfaces between all circuits controlled by the electric box below and the inner tank, which is convenient for separation during maintenance and replacement of parts. Realize fool-like maintenance |

| The rear cover is provided with a repairable window. It is convenient for maintenance |

| The heating tube/solid state/temperature control instrument adopts modular design, which is convenient for maintenance |

| Double cooling on the upper and lower sides of the outlet, the speed is adjustable |

| The upper and lower liner is filled with high-efficiency thermal insulation material under high pressure |

| Electrical and control performance |

| Advanced PLC+ industrial computer control, Taiwan Xinjie furnace temperature test software, the computer can run normally when it crashes |

| The constant low current protects the heating tube/solid state/temperature control circuit from the impact of strong current and prolongs the service life. |

| Set leakage protector |

| The temperature is too high or too low alarm function |

| Self-set ultra-high temperature, automatically cut off the heating power |

| Santak UPS uninterruptible power supply, automatic operation after power failure |

| Powerful temperature curve test and analysis function, which can meet the parameter analysis of various processes, has the function of intelligent fault diagnosis, and can automatically display various faults in the alarm list |

| The file can be named and saved according to the user's different products. When the user changes the product, he only needs to select the corresponding file to adjust the parameters of the equipment. |

| The system has automatic fault diagnosis, ultra-low temperature alarm, and can automatically set the cooling time after shutdown. |

| Control the speed of the fan motor in stages (heating balance area + independent control of the main welding area), stepless speed regulation mode |

| The system will automatically stop heating and enter cooling according to the over-temperature condition |

| Unique balance chain control mode, the temperature auto-adjustment scanning period is 0.1 seconds, reducing the solid-state output and achieving the effect of power saving. Stable temperature control and reduced curve noise |

| With shutdown delay protection function, after shutdown, it will be cooled by air according to the preset time. |

| Cooling System |

| Cooling method: upper and lower double cooling system, the cooling speed is controlled by adjusting the cooling angle. |

| Cooling quantity: two-stage cooling, (wind wheel porous cooling + constant current fan forced cooling) |

| Rosin/exhaust gas recovery system |

![]()

![]()

CONTACT US:sales@smtlinemachine.com